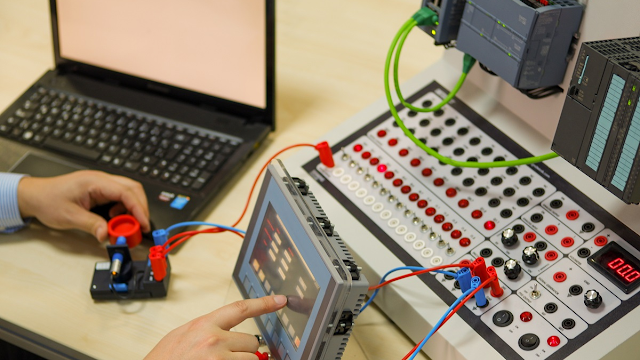

In the dynamic world of industrial automation, Programmable Logic Controllers (PLCs) stand as the backbone of control systems, orchestrating the seamless execution of tasks across a myriad of industries. PLC programming, a niche within the broader field of industrial automation, plays a crucial role in optimizing processes, enhancing efficiency, and ensuring the reliability of complex industrial systems. This blog post aims to unravel the intricacies of industrial PLC programming, exploring its significance, key principles, and the evolving landscape of this indispensable technology.

The Significance of Industrial PLC Programming:

Automation Precision:

PLCs are designed to carry out precise and repetitive tasks with unparalleled accuracy. Industrial processes demand a level of precision that human operators may find challenging to achieve consistently. PLC programming allows for the creation of logic sequences that govern the behavior of machines, ensuring precise execution and minimizing errors.

Flexibility and Adaptability:

One of the remarkable features of PLCs is their flexibility. With the right programming, these controllers can adapt to changes in the manufacturing process or production requirements without the need for extensive hardware modifications. This adaptability is crucial in industries where production lines must accommodate various product configurations and specifications.

Real-Time Monitoring and Control:

PLC programming enables real-time monitoring and control of industrial processes. Through sensors and feedback mechanisms, PLCs continuously gather data on variables such as temperature, pressure, and flow rates, allowing for instant adjustments to maintain optimal operating conditions. This real-time capability enhances overall system responsiveness.

Key Principles of Industrial PLC Programming:

Logic Programming:

At the core of PLC programming is the creation of logic sequences that dictate the behavior of connected devices. These sequences, often written in ladder logic, mimic the electrical relay logic used in traditional control systems. The logical structure allows programmers to design complex control algorithms that govern the sequence of operations in an industrial process.

Input and Output Handling:

PLC programming involves configuring input and output devices that interface with the controller. Inputs can come from sensors, switches, or other devices, while outputs control actuators, motors, or other elements of the industrial system. Efficient handling of inputs and outputs is crucial for the proper functioning of the automated process.

Data Handling and Communication:

PLCs are often part of larger industrial networks where communication between devices is vital. Industrial PLC programming includes protocols for data exchange, ensuring seamless communication between PLCs and other components of the automation system. This communication facilitates coordination and synchronization of processes.

Error Handling and Diagnostics:

Robust PLC programming includes provisions for error handling and diagnostics. This involves the implementation of alarms, error codes, and fault detection routines to identify and address issues promptly. Effective error handling contributes to system reliability and minimizes downtime.

The Evolving Landscape of Industrial PLC Programming:

Advanced Programming Languages:

While ladder logic remains a staple in PLC programming, advanced programming languages such as Structured Text and Function Block Diagrams are gaining prominence. These languages provide more flexibility and modularity, allowing programmers to create complex algorithms with greater ease and readability.

Integration of Industry 4.0 Technologies:

The advent of Industry 4.0 has brought about a paradigm shift in industrial automation. PLC programming is now integrating with technologies such as the Industrial Internet of Things (IIoT) and cloud computing. This integration enables data-driven decision-making, predictive maintenance, and remote monitoring, ushering in a new era of smart manufacturing.

Simulation and Virtual Commissioning:

To reduce downtime and enhance the efficiency of PLC programming, industries are increasingly adopting simulation and virtual commissioning. These tools allow programmers to test and validate their logic sequences in a virtual environment before deploying them to the actual PLCs on the factory floor. This approach minimizes the risk of errors and accelerates the commissioning process.

Cybersecurity Considerations:

As industrial systems become more interconnected, the importance of cybersecurity in PLC programming cannot be overstated. Ensuring the integrity and security of PLC code is crucial to prevent unauthorized access and potential disruptions to industrial processes. Robust cybersecurity measures are now an integral part of modern industrial PLC programming practices.

Conclusion:

Industrial PLC programming is a linchpin in the world of industrial automation, enabling precise control, flexibility, and real-time monitoring of complex processes. As technology continues to advance, PLC programming is evolving to meet the demands of Industry 4.0, integrating with cutting-edge technologies and embracing advanced programming languages. The future promises a landscape where smart manufacturing, data-driven decision-making, and virtual commissioning become standard practices, further optimizing industrial processes. As industries continue to rely on the efficiency and reliability of PLC programming, the role of programmers in shaping the future of automation remains pivotal, ensuring that industrial systems operate at the peak of their potential.